质量控制

①拌色粉

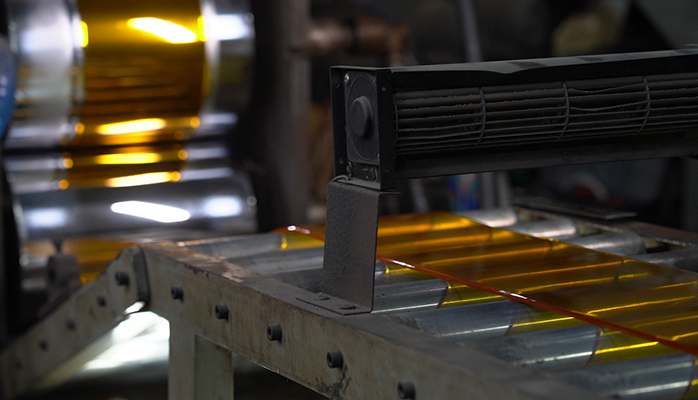

②拉板

③压板

④抛光

⑤选料

⑥外壳

⑦脚丝

⑧点焊

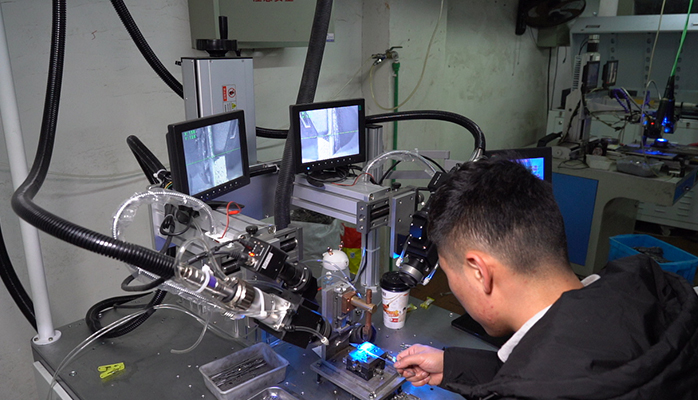

⑨检验

⑩CNC

⑪钉胶

⑫打肶

⑬组装

⑭打磨

⑮装片

⑯扶架

Color mixing powder

It's the process of blending colored

powders to create custom colors for plastic eyeglass

frames before they are molded into shape.

Pull plate

It's the process of heating and stretching a block of

acetate to make it longer, thinner, and more dense, which

prepares it for cutting into eyeglass frames.

Pressing plate

It is a method of shaping a heated sheet of

acetate by pressing it into a mold to create the basic

flat shape of an eyeglass frame front or temples.

Polishing

It is the process of smoothing and shining the surface

of the rough-cut acetate "shell" to prepare it for further

detailed carving and finishing.

Material selection

It is the crucial first step of choosing

the specific material that will be used to

make the eyeglassframes. This decision determines

the glasses'look, comfort, durability, and price.

Make the shell

This is the core process of cutting the rough,

flat shape of the eyeglass frames out of a block or

plate of material (like acetate or metal).

Temple

It is the process of creating the arms of the

glasses.This involves shaping the material,

attaching hinges, and ensuring a comfortable

fit behind the ears.

Spot welding

It is a technique that uses a quick electrical

current to fuse small metal parts of an eyeglass

frame together at specific points. It's like using

targeted heat to create tiny, strong welds.

Quality inspection

It is the critical quality control step of

carefully checking the metal components

(like frames and temples)for any defects before

they are assembled into finished glasses.

CNC

It is a highly precise manufacturing process where a

computer-controlled machine uses cutting tools to automatically

carve, shape, and drill eyeglass frames from a solid

block of material (like acetate or metal).

Glue bonding

It is the process of using a special adhesive to

permanently attach two parts of an eyeglass

frame together.

Hinge fitting

It is the precise process of attaching the hinges

to the front of the frame and the temples (arms),

allowing the glasses to open and close smoothly.

Assembly

It is the process of where all the individual

polished parts are put together to create a

complete, functional pair of glasses.

Finish polishing

It is a final hand-polishing step where a craftsman uses

a rotating cloth wheel and a special wax compound

to create a brilliant, high-gloss shine on the

eyeglass frame.

Lens mounting

It is the final assembly step where the finished lenses

are securely fitted into the eyeglass frame.

Frame adjustment

This is the final, custom fitting process where an optician

carefully bends and adjusts the glasses so they sit comfortably

and correctly on the specific wearer's face.